Modern Engineering & Tool Steel

Over the last few decades there have been tremendous developments in production efficiency, service life analysis, and machining technology. But what about the steel?

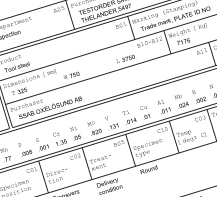

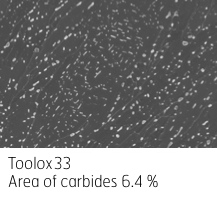

Most of the steel in the market is based on specifications too old to keep up with the realities and requirements of today’s workshops and end customers. Toolox is a modern, ready to use engineering and tool steel designed to address exactly this. Based on a low alloy concept, Toolox offers best in class crack resistance, dimensional stability, and precision. And it allows you to eliminate the heat treatment process.